|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||

It’s no secret that automation is a hot topic right now in virtually every industry. The ability to use software to save employee hours and costs and defer that burden to a machine that can process tasks in a fraction of a second is essential for any business with low-profit margins, like the restaurant industry.

After all, every task is critical, and every second counts when your employees are on the clock. And when it comes to finance processes like invoice reconciliation, EDI and automation are rapidly changing the way companies approach these tasks.

This article will explore EDI and invoice reconciliation, and how adding EDI can benefit your business over the long run.

Any process that a human can do, a machine can do faster and more efficiently, even tasks vital to a business’s profitability, like invoice reconciliation. It is essential to reconcile your invoices as accurately as possible. Doing so will reap the following benefits for your company:

Companies are using automated invoice reconciliation to scale up their business processes, especially in centralized billing. If you own or operate several establishments, you will need to process invoices from multiple locations quickly and efficiently. EDI allows you to do this, even if your various locations are being run independently by different managers.

By using EDI and automating the manual collection of data, you can reduce processing errors and increase efficiency when reconciling invoices. Messy handwriting, wrong inputs, and scanning issues are no longer a problem. You can enter all the pertinent information into a terminal, generate an invoice electronically, and send a copy to a centralized office for automated reconciliation.

Automated EDI is one form of IT management that is transforming business infrastructure and processes. Automation reduces complexity and increases efficiencies that can affect whole work teams, replacing manual, error-prone processes, and saving many more useful employee hours spent on other tasks.

How is your company leveraging powerful cloud EDI functionality and automation to transform your invoice reconciliation processes?

Tangentia provides digital solutions for businesses of all sizes. If you’re looking to kickstart your automation journey, we can help. Get in touch with one of our EDI specialists today to get started.

Tangentia is a Platinum Partner of IBM and well as partners with Automation Anywhere, UI Path, Blue Prism, Adobe, Microsoft, Salesforce, Amazon and leading enterprise software vendors. We work with customers globally with offices in Canada and India to implement their RPA strategies using an agile methodology.

Read Now

The holidays are fast approaching, and that means retailers and wholesalers must be efficient in organizing their products and managing the inventory of their products.

Depending on the size of your operation, how you manage your products may differ. However, warehouse inventory management is not just a requirement for compliance with SEC regulations and the Sarbanes-Oxley Act (SOX) for public companies—it’s crucial to the success of any retail company.

We’ve put together this brief guide to help you understand the basics of warehouse inventory management.

Warehouse inventory management is the system used to organize and track all of the company's owned products. For warehouse operations, this helps to ensure the right level of inventory is in the right place at the right time. Inventory is then converted to revenue once it’s sold.

In the United States, manufacturers, retailers, and merchant wholesalers carried more than $1.9 trillion in inventory in June 2018, according to the U.S. Census Bureau.

Accurately evaluating the inventory for the company’s balance sheet requires either physical stock count or an automated inventory system that creates an accurate record of each inventory-related transaction.

This quantitative product management differs slightly from a company’s warehouse management system (WMS), an umbrella term that supports the entire operation of a warehouse, including inventory management.

The best warehouse inventory management systems keep track of products and provide actionable business intelligence, such as identifying trends in product performance and sending reorder notifications when stock is low.

Current warehouse inventory management systems are outdated and often haven’t embraced everything automation has to offer.

There are many steps involved in warehouse inventory management, some of which include:

Every step of the delivery, tracking, loading, and data manipulation is done by workers. This manual system can increase the risk of human error at any point in the inventory management process. If there is ever a mistake, the only method of resolving the problem is another manual re-do.

Another downside to this type of inventory management is its unsustainability for more significant warehouse operations. Without computerized report generation, companies may see difficulties in turning paper-based information into useful data.

This system uses the familiar label of black stripes that are affixed to the product, packaging, or pallet. Using wearable barcode readers, workers can speed up warehouse inventory management and save seconds scanning per item. This digital format is efficient and accurate by counting goods in real-time.

Radiofrequency identification tags are found in two configurations: active and passive. Active systems use battery-operated tag readers located throughout a warehouse and updates of inventory count and location. Passive systems are read-only when someone activates the readers through hand-held devices. Passive technology can be read at up to 40 feet, while active readers are effective up to 300 feet, but both systems automatically record inventory.

With growing advancements in technology and automation, companies are starting to turn to optical systems mounted on the ground or aerial platforms. These systems use machine learning to read existing labels without barcodes or RFID and maintain accurate, up-to-date inventory.

Modern supply chains are more complex than ever. Traditional manual processes are no longer viable for businesses that want to optimize workflows and reduce wasted resources.

Automation is the natural solution to these problems. It’s ideal for individual warehouses or companies that support numerous locations across the entire supply chain.

Effective fulfillment requires sophisticated solutions that are able to predict trends, make actionable recommendations, and increase the visibility of potential issues before they turn into larger problems.

Successful manufacturers, 3PLs, and retailers know the importance of optimized supply chains. That’s why they’ve heavily invested in cloud-based automation solutions for their supply chains.

Here at Tangentia, we understand the transformative difference automated solutions can make for your business.

When you’re processing hundreds or thousands of pallets or cartons per day, automated processes can significantly save time, effort, and costs. For many retail companies, creating greater warehouse inventory management efficiency translates to a multi-million dollar impact.

Are you interested in learning more about warehouse inventory management automation? Get in touch with Tangentia today to learn more.

Tangentia is a Platinum Partner of IBM and well as partners with Automation Anywhere, UI Path, Blue Prism, Adobe, Microsoft, Salesforce, Amazon and leading enterprise software vendors. We work with customers globally with offices in Canada and India to implement their RPA strategies using an agile methodology.

Read Now

Tangentia is a leading provider of digital transformation solutions worldwide. They empower companies of all sizes with proven Automation, B2B, and Digital integration solutions and strategies that help their clients maintain a competitive edge.

In 2020, the Tangentia Jigyasa Quiz in its 4th edition was held in 6 Indian cities with the finals in Goa and more than 200 teams participated in the quiz. Tangentia embraced Covid-19 as a new normal and undertook measures to keep their customers and employees engaged some of which like the Tangentia Talkies got a lot of attention from the global and local press.

Tangentia’s proactive engagement with customers, prompt and timely deliverable even during the lock-down, launching innovative ways such as Webinars and campaigns to showcase continual progress, and automating its processes has kept the company a client favourite all along.

Where the global COVID-19 outbreak has led to the partial collapse of most essential and non-essential business organizations, Tangentia has risen above the storm and introduced a unique remote employee engagement program namely ‘Tangentia Talkies’ to embark upon the stumpy self-esteem of its employees and ensure connectivity with one another.

“Covid-19 has shown us new ways to work together as a company. ‘Tangentia Talkies’ will be a corner-stone of our new HR engagement strategy. Our team motivation and bonding has been strong during these tough times and one of our mantras for success is to communicate, communicate, communicate.” Vijay Thomas, Founder-CEO, Tangentia Technologies.

‘Tangentia Talkies’ is a day-to-day online gathering that is conducted on the Google Hangouts platform wherein an employee is given an opportunity to make a presentation for a brief duration of about 10 to 15 minutes concluding with a quick Q&A session. This unique initiative as its name itself denotes provides a ‘talk show’ like experience to the participants that begins with a theme song, goes on to start the presentation and concludes with the rolling of final credits and applause for the speaker of the session.

The range of topics that are discussed during these sessions is abundantly broad to an extent that it enables speakers to converse about their passion, enlighten the audience about their surreptitious talents or just articulate upon a topic that could spread awareness in society. Few issues that have been discussed so far through this one-of-a-kind forum are ‘Trust in the Digital Era’ presented by Rajhans Gupta (Sales Manager), ‘Importance of Mental Health’ presented by Malav Kansara (Staffing Manager), ‘Mystery Called Dreams’ presented by Shweta Kandri and many more!

Click here to Read the complete article

Tangentia is a Platinum Partner of IBM and well as partners with Automation Anywhere, UI Path, Blue Prism, Adobe, Microsoft, Salesforce, Amazon and leading enterprise software vendors. We work with customers globally with offices in Canada and India to implement their RPA strategies using an agile methodology.

Read Now

When it comes to your company’s supply chain, one of the most common weak links is inventory management. There are very few businesses that handle their inventory management well. Typically, retail businesses face problems scaling up their inventory management systems as they grow.

As your business grows, efficient inventory practices become more and more worth investing in. Retail companies with poor inventory management can suffer from stock issues, slowed turnover times, and needing to order excess inventory to prevent running out of stock. Slow delivery and stock issues are a sure way to reduce customer satisfaction, so keeping these issues at a minimum is important.

How can retail companies improve their stock management and inventory processes? For most businesses, the answer is automation. Most inventory management issues stem from human error, inefficient practices, and incomplete item information. Automation resolves all these issues. It is intrinsically efficient and requires complete item information, and eliminates human error.

So, how can your business get started with inventory automation? The process isn’t as difficult as you might think. Just-in-Time Inventory (JIT), Electronic Data Interchange (EDI), and Robotic Process Automation (RPA) are a few strategies that you can utilize onto your supply chain to be well on the way to an optimized system.

JIT inventory is a way to decrease waste and increase the efficiency of your supply chain. With JIT, your supply chain only receives goods as they become needed.

JIT keeps your business at maximum efficiency. By having goods on hand only when they’re needed, you can keep your supply chain operating smoothly without needing to worry about long-term storage of stock.

Maintaining JIT inventory reduces the amount of waste your supply chain produces from leftover, unused goods. It also keeps the investment into your supply low, as you don’t need to stock more goods than you need.

While JIT keeps your business on top of its efficiency when supply is readily available, it can cause your business to suffer greatly from issues farther down the line of the supply chain.

Since you don’t keep a stockpile of the goods your supply chain uses, if they suddenly become scarce or expensive, your business might unexpectedly run out of stock. You might also end up needing to buy overpriced stock.

In general, Electronic Data Interchange is simply the technical term for two computers communicating with each other. In the context of the supply chain, EDI is a way to get a full digital picture of your electronic transaction exchanges with your customers, as well as your inventory.

Many supply chain issues, such as inventory shortages and surpluses, happen because of a lack of inventory visibility. EDI allows you to keep track of all your inventory in one centralized location, making it easy to track and prevent inventory errors.

With EDI, it’s also much easier to manage more complex inventory processes, such as multichannel sales. The more complicated the process, the more likely it is for human error to occur.

Having a guarantee that all of the information about your inventory is accurate allows you to make supply decisions with the big picture in mind. Overall, EDI improves almost all aspects of the inventory management process.

EDI can be hard to adjust for your supply chain to work around, especially if it is a legacy EDI system that is in place. This is especially the case for rapidly growing businesses, which don’t usually have particularly well-optimized supply chains.

If your inventory isn’t well-suited to EDI, it can take some work to get full value out of the EDI system. You may need to overhaul some of your inventory processes altogether.

RPA is a way to increase the efficiency of your inventory management by replacing human operators with various digital systems. With an RPA system, the computer essentially uses itself by means of a virtual operator, called an RPA robot.

RPA robots have a wide array of functionalities and are able to completely replace human users for many applications. They can perform tasks such as moving and collecting data from various sources, as well as process data by performing calculations.

RPA can allow for quite a lot of inventory management automation, sometimes up to 90%. In general, processes that can be automated should be, as humans are almost always slower than an RPA robot. RPA robots can drastically increase the efficiency of your inventory management processes.

Like EDI, RPA removes the human element from many processes. In particular, RPA robots can handle data entry, data processing, and other repetitive tasks easily, with a 0% rate of error. This gives them a sizable advantage over humans, who are unable to focus on these tasks for as long.

RPA systems can also keep running overnight, giving them yet another advantage over human operators. Overall, RPA is almost guaranteed to provide a large boost to your business’s supply chain efficiency.

Like EDI, a proper RPA system is not trivial to implement. Rolling out an RPA project into your business’s inventory management or production environments actually has a good chance of failing at first. After some troubleshooting, you will likely start getting full value out of the RPA system.

Automation is a great way to increase efficiency and eliminate errors within your inventory management process. It can’t do the job on its own, though: if you want to optimize your inventory management, you should use a combination of JIT, EDI, and RPA.

On their own, these three methods of optimizing your inventory are sure to increase your efficiency significantly. When put together, though, they are more than the sum of their parts.

The biggest weakness of JIT is that it’s prone to human error. Improper data entry can result in an unexpected stock outage of your product. EDI and RPA prevent this by removing the capacity for human error in the majority of the inventory management operation.

On the other hand, EDI and RPA can suffer from bottlenecks. It doesn’t matter how efficient your data processing is if your business is bogged down by extra costs relating to storage or other inefficiencies. JIT helps alleviate this bottleneck by increasing the efficiency of your business outside of data processing.

While JIT, EDI, and RPA are tools that are best used together, they can be used individually to great effect. You should make sure you’re on the lookout for the potential issues with using these tools.

So as long as you build your inventory management process around the tools you’re using—you should be able to work around JIT, EDI, and RPA’s various weaknesses. Overall though, we recommend trying to implement all three inventory management tools, as they work best in tandem.

If your business has been growing and you’re having trouble handling demand for your products, the solution may not be to expand and spend more. Oftentimes, it’s much more budget-friendly and effective to invest in ways to improve your efficiency than expand your flawed, existing system.

When it comes to improving the efficiency of your supply chain, the best way is with automation. JIT, EDI, and RPA are all easy-to-implement forms of automation that are designed to provide you with a quick return on investment. Once you have these systems in place, you’ll find that your inventory management model is much more scalable.

If you’re interested in learning more about JIT, EDI, or RPA, feel free to contact us today to find out how these tools can help your business be the best it can be.

Tangentia is a Platinum Partner of IBM and well as partners with Automation Anywhere, UI Path, Blue Prism, Adobe, Microsoft, Salesforce, Amazon and leading enterprise software vendors. We work with customers globally with offices in Canada and India to implement their RPA strategies using an agile methodology.

Read Now

Everyone’s heard about Electronic Data Interchange (EDI) systems by now. But seamlessly integrating EDI data into an Enterprise Resource Planning (ERP) system is one area where many companies struggle. It’s important that these two systems communicate flawlessly to minimize processing times, eliminate errors, and avoid compliance issues.

Many companies rely on EDI systems that they struggle to maintain as they start to transition into the era of cloud technology. Most of them are legacy EDI systems that have been patched along over the decades, and trying to make them compatible with modern ERP systems is often a challenge.

So, how can you ensure that your EDI data is compatible with your ERP system? Let’s start by assessing the types of problems that most companies face when trying to integrate their EDI data with their ERP.

Let’s face it—incorporating your EDI data into your ERP system isn’t an easy task. Here are a few of the most common problems you’ll encounter:

Every organization is unique, and the challenges you face may be different. Still, your main focus should always be on maintaining the integrity and accessibility of the data that is essential to your business and your customers.

Several options exist when it comes to integrating your EDI data into an ERP system. The most popular options include:

Some companies use a Third-Party EDI Integration Plugin that acts as a bridge between their EDI and ERP systems. While this may prove successful for your organization, the cost associated with this option is typically high.

Third party EDI service providers not only ensure your EDI compliance with your trading partners’ EDI requirements, but they also typically offer ready-to-use integration modules for most ERPs. Many companies rely on Third Party EDI Service Providers to fully manage their overall EDI infrastructure, freeing them from costly in-house management and maintenance of these systems.

The more modern ERP, WMS and eCommerce platforms have started to embrace web services/API integration to allow their applications to seamlessly communicate with other applications. EDI data can be incorporated into your ERP by utilizing APIs.

Flat files are known as text database files. They are the most basic form of EDI data available. This method uses simple text files called flat-files (or CSV) to ensure data is compatible with the majority of ERP systems. Other EDI systems may use the XML format. These two file formats are the global standard in EDI and are highly-integratable with other ERP solutions.

Integrating your EDI data into an ERP system is a major process that every organization that handles huge amounts of data should consider. Tangentia specializes in fully integrated EDI solutions, and can help your company successfully build the bridge between your EDI, ERP, WMS, eCommerce and other business applications.

Tangentia has decades of experience working with EDI systems, and we understand exactly what it takes to build an automated system that is flexible, compliant, and functional while being cost-effective.

Get in touch with a member of the Tangentia team today to see how we can automate your EDI data flow between your existing business applications.

Tangentia is a Platinum Partner of IBM and well as partners with Automation Anywhere, UI Path, Blue Prism, Adobe, Microsoft, Salesforce, Amazon and leading enterprise software vendors. We work with customers globally with offices in Canada and India to implement their RPA strategies using an agile methodology.

Read Now

SWIFT is a messaging network designed to facilitate the global transfer of funds. It works by sending electronic messages from one financial institution to another to notify them when a transfer of funds is made.

Each year, SWIFT updates its service based on changes requested by their customers. This update is the MT Standards release and it ensures the message types (MTs) exchanged by SWIFT users continue to meet their needs, both for existing businesses and new businesses.

The release for 2020 is called the Standards MT November 2020 and includes the following

changes:

Applying the changes in the SWIFT Standards Release Guide is mandatory for all financial institutions. However, making the required changes can be costly and it is important to balance that cost against the resulting benefits.

Tangentia can help with the update process, ensuring it is as efficient as possible and minimizes costs, while ensuring full compliance. We have extensive experience implementing SWIFT EDI gateways using solutions from IBM WebSphere Transformation Extender (WTX), IBM Sterling B2B Integrator, GXS, TIBCO and others.

Contact Tangentia for more information on SWIFT 2020 updates.

Tangentia is a Platinum Partner of IBM and well as partners with Automation Anywhere, UI Path, Blue Prism, Adobe, Microsoft, Salesforce, Amazon and leading enterprise software vendors. We work with customers globally with offices in Canada and India to implement their RPA strategies using an agile methodology.

Read Now

2019 was a significant year for Tangentia. As a recognizable ‘global boutique’ consulting firm that provides bespoke services in Canada, USA and India—we are excited about the progress we saw.

Whether it was our core B2B business of EDI(Electronic Data Interchange) and Ecommerce or the development of our new AI(Artificial Intelligence) and RPA(Robotic Process Improvement) segment, we empowered many businesses to improve their core operations.

But what trends really defined 2019? And which ones will continue to lead the way into 2020?

2019 was the year we committed to automation through our AI and RPA service offerings. While we had some exposure previously (mostly through providing staffing solutions), we expanded our offerings by creating a new range of services that focused on key problems that businesses face in a multitude of industries. We expanded our partnership with IBM to become a Platinum partner of IBM for Watson AI. Also we are global partners for Automation Anywhere, UI Path and Blue Prism in the RPA space.

We also consolidated some of our legacy services, improving our B2B business segment—which includes our legacy EDI and Ecommerce business. These services continued to grow substantially outside of North America with many significant wins in 2019 in India including India’s largest retailer.

Our global headquarters also moved in Toronto, from Willowdale to the Waterfront district, which saw us join the likes of Google,Uber, LCBO, Royal Bank, and soon Microsoft in what is arguably the fastest-growing tech hub in the world. We are beyond excited to be located in such an innovative area of the city.

Company accomplishments are important, but the real value is in the lessons we learned from the exciting technologies that we offer.

So, what were the main takeaways from 2019?

The RPA industry saw between 600-1000% growth in 2019. These numbers are large and signify that many companies are investing in this technology heavily. Major players in this industry have become unicorns in the investing world as the markets realize the potential that automation has.

However, AI, RPA, automation, and similar technologies aren’t a guarantee. Companies that invested millions into this technology without a plan saw minimal results.

Automation is a catalyst for innovation, but your business needs the right systems in place to take advantage of it. The goal of RPA is to enhance existing systems that are already working. An automation solution will decrease costs, improve efficiency, and other core metrics- but only if an organization understands what areas they need to improve.

It’s important that a company makes small changes that compound over time. We encourage our clients to push for real value and not to fall victim to the marketing pitches that they’ve heard about automation. Our team even has a Continual Process Improvement(CPI) using RPA model that we encourage our customers to try out.

In 2020, we expect to see more companies identify how RPA can help their organization cut costs, improve productivity, and make their business more agile.

Yet again, critics made the claim that EDI is dead. But as an EDI solution provider, I can assure you that EDI isn’t going anywhere.

If anything, EDI is evolving and adapting to the digital age. At Tangentia, we see EDI as any B2B communications between two business entities and not through the traditional lens of ANSI X12 or EDIFACT. And while this traditional EDI may be slowing down, XML and API formats aren’t going anywhere—especially in the age of integration. Today, businesses rely on countless apps having the ability to communicate and synchronize flawlessly. This alone will ensure the longevity of EDI as companies look to simplify B2B communications.

Legacy companies will always rely on some form of EDI, while modern startups have the benefit of building out in the digital world. Still, even startups require EDI solutions using either the XML or API formats.

Digital transformation is the buzzword today. Every company is claiming they are making a digital transformation.But what does it really mean?

An effective digital transformation should be all about making incremental changes that drive long-term value and improve the user experience.

For example, a business may use an invoicing system that takes one month to complete. They could realize substantial gains by automating this process down to several days.

One advantage that we can offer our clients is the perspectives we have gained from working in Canada, the United States, and India. We can help companies identify what’s working in one region and find ways to adapt that same technology in another.

Digital transformations aren’t going anywhere in 2020. Successful companies are always looking to modernize and improve the way they connect with customers, employees, and partners. However, we expect to see companies focus more on what their personalized digital transformation looks like.

Our unique agile approach to digital transformation has allowed us to deliver complex digital transformation projects for the largest beverage alcohol distributor in the world, the largest retailer in India and many mid sized companies worldwide. We will continue to stay true to our belief in the power of the iterative agile delivery model.

Tangentia is a ‘global boutique’ firm. We know how to execute using a global delivery model with much less overheads than our competitors and that provides our customers with high-end services at a value driven price.

Interested in Automation but don’t know where to start? Looking for somebody to help maintain, support and enhance your existing bots? Or just want to say hello? Contact us now. We promise a human will answer your query, not a bot.

Contact Us

The latest trends in the marketplace have shown that companies have begun to be more and more open to keep their data on the cloud. This is fast becoming true with their ERP systems. For Microsoft, it is not just a strategic decision to therefore re-brand their ‘on premise systems’ but a means of keeping up with the competition. Customers these days are not just looking for an ERP system that handles the finance and operations of the company but also embeds ecommerce solutions. This allows for a one stop shop cloud based solution that companies can exponentially benefit from.

Keeping the above in mind Microsoft has introduced ‘Dynamics 365 Business Central’ (formerly known as Microsoft Dynamics Navision) which is available on both “Premise” and on “Cloud.” Business Central offers organizations a single, end to end solution for managing finances, operations, sales and customer service and a solid opportunity to easily upgrade from entry-level accounting software and legacy systems.

Business Central is customizable and brings the full power of Dynamics NAV to the cloud. One of its most telling features – it provides businesses with tools that they can use to analyze their cash flow by analyzing historic data to make predictions for future periods. The cash flow forecast feature is made all the more dynamic as it can utilize the Azure Machine Learning to model various scenarios and provide groundbreaking insights into what to expect for the future. Azure Machine Learning allows the business to extend the time horizon for cash flow forecasts. It has the following models to calculate forecasts:

What it does differently is that it applies advanced statistical methods to the historical data to generate data in the future and include that data when calculating the forecast. When we predict receivables or payables, we use the due date as a date field and not the document date or posting date, so we don’t need to define and apply a payment term to the predicted results.

Azure ML is free in Business Central; you just need to turn it on. If you have two years of data, you can expect to forecast values accurately for up to four months. Business Central has introduced a ‘threshold’ factor that can be adjusted in the Cash Flow Forecast setup. The field is called “Variance %” and allow you to specify range of deviation, plus or minus, that you’ll accept in forecast.

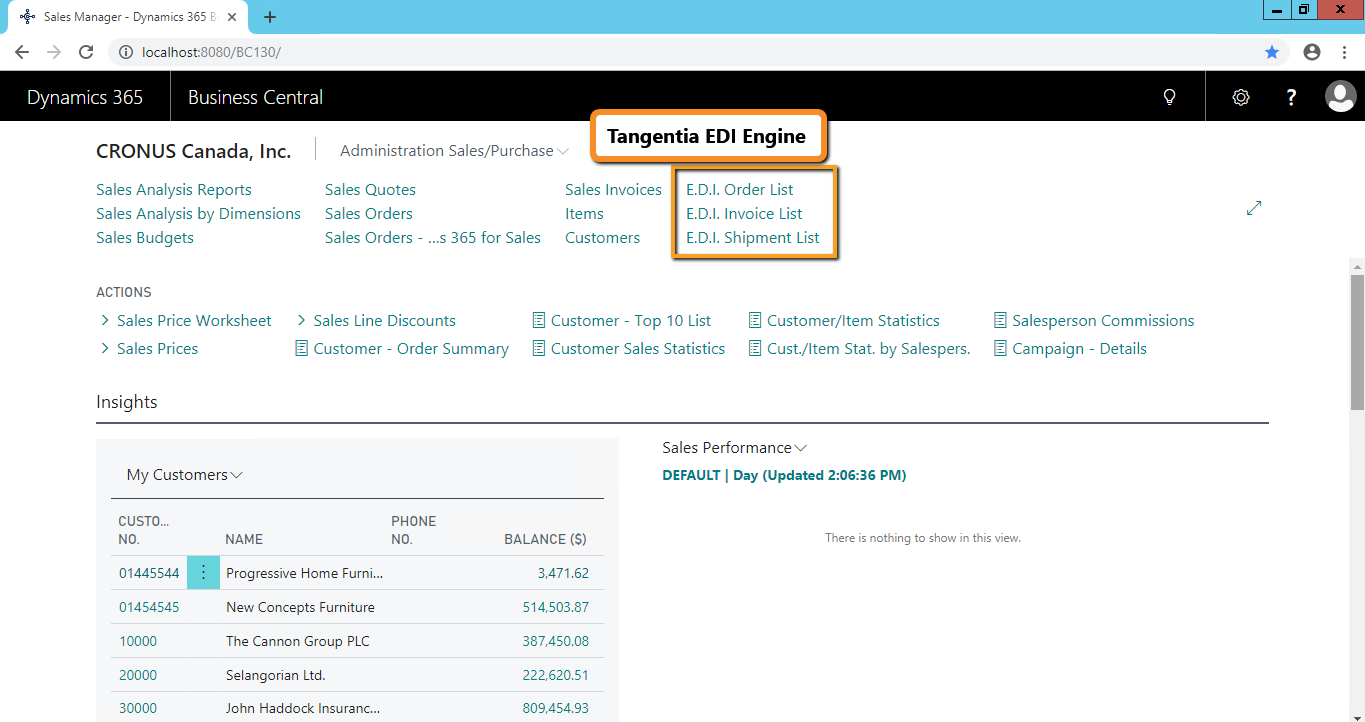

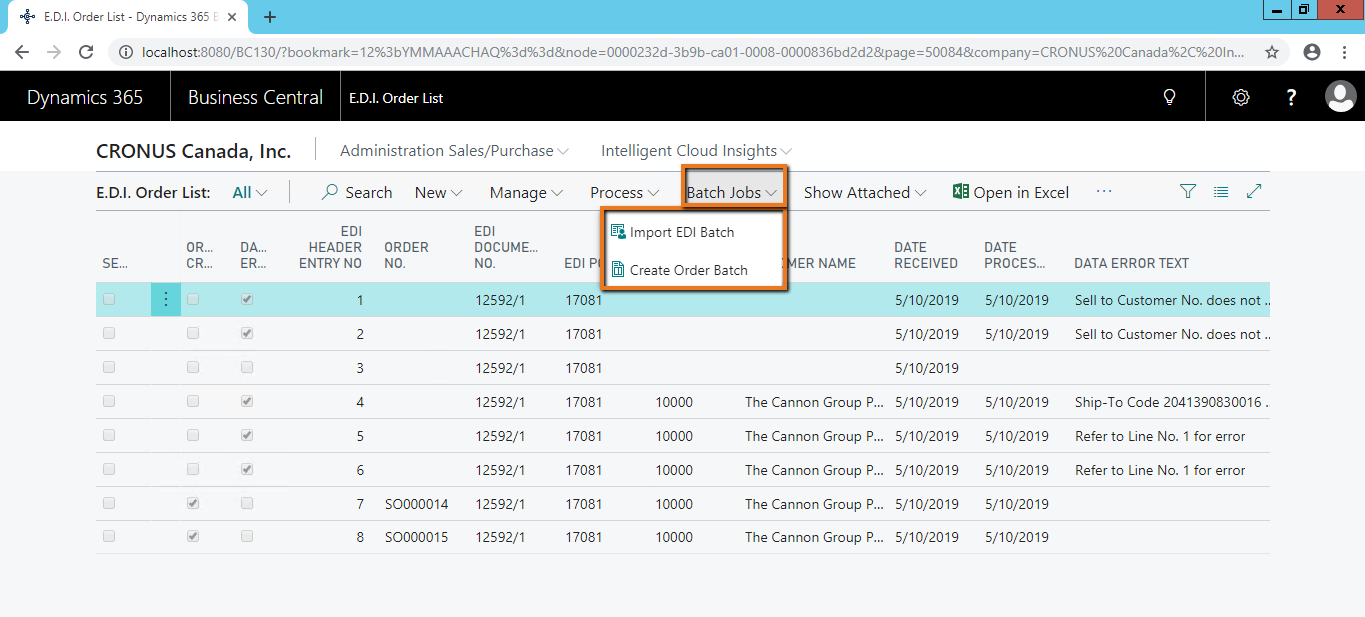

Tangentia has been at the forefront developing custom integration solutions that has previously connected the client’s Microsoft Navision ERP system to their Electronic Data Interchange (EDI), ecommerce and Warehouse Management Systems. (WMS)

The Tangentia Navision Engine (TNE) has supported MS NAV version 4.0 all the way to MS Dynamics NAV 2018. As of May 2019, Tangentia Navision Engine also seamlessly integrates and connects your EDI trading partners with the Business Central Cloud ERP. TNE has the following features:

RPA is making a real impact in enterprise space and empowering knowledge worker by helping them focus on the more meaningful and value-added side of their work and offloading more mundane and repetitive tasks to an RPA powered robot. There is an enterprise workforce revolution underway led by RPA and AI/Cognitive technologies.

There is a plethora of solutions providers in this space, each with its own specialty. However, there are three main vendors that come to mind. They are – Automation Anywhere, Blue Prism and UiPath in alphabetical order. Among these, UiPath is probably the fastest growing since it has recently received funding from big Silicon Valley Venture Capital firms in series C and D rounds.

Gartner predicts that by 2022 worldwide RPA spending will total $2.4B with an expected CAGR upwards of 30% in the next five years.

Here are some of the trends:

Tangentia provides end to end implementation services around the three main automation solutions – Automation Anywhere, UiPath and Blue Prism. Some of the benefits of choosing Tangentia are:

Identifying and working with a right partner is the most important and crucial step to ensuring a successful RPA journey.

With Tangentia’s EDI, Automation, and Ecommerce services, we can provide a complete streamlined Procure-to-Pay process for the Global enterprise. The Procure-to-Pay (P2P) is an end-to-end process starting with requisitioning goods and services and ending with making payments for them.

The 7 Steps Procure-to-Pay process involves:

This apparently simple process can be complex due to legacy systems, and errors from manual entries, leading to unnecessary costs. Implementing an Procure-to-Pay cycle can provide an opportunity to bring efficiency to the process and save costs.

With Tangentia’s EDI, Automation, and Ecommerce services, we can provide a complete streamlined Order-to-Cash process for the Global enterprise. Order-to-Cash (OTC or O2C) is the top-level business process for receiving and processing customer orders.

The order to cash process is simple and can be illustrated with the following steps:

Order-to-Cash systems affect all areas of a business and are critical to operational success.

In a standard system, orders are received via different sales channels, such as phone, emails, fax, online channels or through sales persons. This input complexity added with other manual entries, makes the process error-prone and the system inefficient. Implementing an Order-to-Cash cycle can provide an opportunity to bring efficiency to the process and save costs.

With Tangentia’s EDI, Automation, and Ecommerce services, we can provide a complete streamlined Order-to-Cash process for the Global enterprise.

The author, Akash Singh is the Head of Project Management Operations(PMO) at Tangentia. He oversees projects around EDI/ Ecommerce/ RPA and AI from a delivery standpoint ensuring client satisfaction and success.

Tangentia is an expert in implementing Digital Transformation solutions leveraging technologies like RPA, Artificial Intelligence, EDI and Ecommerce.

Tangentia implements solutions around Microsoft Dynamics 365 Business Central and you can learn more here.

To learn more about Tangentia EDI solutions Click Here

Interested in Automation but don’t know where to start? Looking for a reliable Automation reseller with the best possible pricing? Looking for somebody to help maintain, support and enhance your existing bots? Or just want to say hello? Contact us now. We promise a human will answer your query, not a bot.

Contact Us